Agricultural Ventilation: EC motor vs AC Motor, Which One Should You Choose?

EC Motor or AC Motor : Which One Is Right for Your Livestock Barn?

In a poultry barn, hog barn, or dairy facility, ventilation isn’t a luxury — it’s essential.

It removes heat, moisture, dust, and harmful gases like CO₂ and ammonia (NH₃).

Without proper airflow, animals eat less, grow slower, get sick more often…

and ultimately, your farm’s profitability takes a hit.

But there’s a well-known downside: ventilation is one of the largest expenses after feed.

Ventilation Costs: A Major Operating Expense

According to RMT Livestock & Environment:

- In broiler production: ≈ 15% of total operating costs

- In hog barns: ≈ 39%

- In dairy: even with natural ventilation, circulation fans running continuously during heat events quickly add up

This is why choosing the right fan motor matters. Between a traditional AC motor and a modern EC motor, the difference in performance and efficiency is huge. Here’s what every livestock producer should know before upgrading their ventilation system.

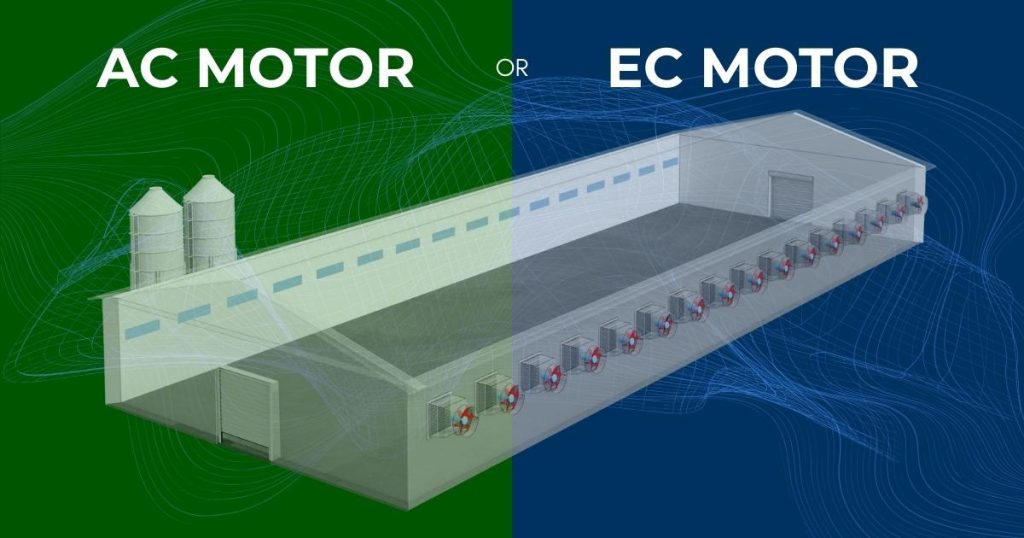

AC Motor : Reliable, but Limited

AC (alternating current) motors have been used on farms for decades. They are robust, dependable, and more affordable upfront. But they’ve reached the limits of what they can deliver for today’s livestock operations.

AC motor advantages

- Lower purchase cost

- Durable and easy to install

AC motor drawbacks

- Low efficiency at reduced speeds

- High inrush current at startup (puts stress on the electrical system)

- Requires a variable frequency drive (VFD) to modulate airflow (extra cost)

- Mechanical wear (belts, brushes) and more maintenance

In short, AC motors may fit a tight budget or simple ventilation needs — but they use more energy, especially when running at lower speeds.

EC Motor : The New Generation of Energy-Saving Technology

EC (Electronically Commutated) motor combine permanent-magnet technology with integrated electronics.

They’re now widely installed in farms aiming to cut energy costs and improve climate stability.

Their benefits speak for themselves:

The biggest advantage: EC motor can automatically adjust their speed when airflow or pressure changes, maintaining the target airflow at all times.

That’s continuous modulation.

Key Benefits of EC Motors

- High energy efficiency: up to 40% savings in dairy buildings and 50–70% in hog barns compared to standard AC motors

- Continuous modulation: precise control using a 0–10 V signal, no external VFD required

- Soft start: fewer current spikes, less stress on your electrical network

- Durability & quiet operation: no capacitor, reduced heat, less noise

- Smart compatibility: works with 0–10 V controllers, automation systems, and all common sensors (CO₂, NH₃, temperature, humidity)

In real-world use, EC fans run at lower speeds most of the time — reducing noise and energy consumption.

Ideal for barns aiming for a stable climate without wasting power.

Automation & Animal Comfort

EC motors integrate perfectly with modern barn controls. For example, GENIUS iTouch controllers paired with the FarmQuest platform allow you to manage ventilation, heating, and lighting right from your phone or computer.

You can:

- Adjust fan speeds in real time

- Receive alerts if something goes wrong

- Monitor barn conditions remotely

This connected-farm approach keeps the climate stable, supports better animal performance, and reduces energy costs — even when you’re out in the field.

Profitable …but Even More Importantly, Stable: The Real Advantage of EC Motors

Producers often ask: “Yes, they cost more… but are EC motors really worth it?”

The answer is yes for several reasons.

Return on Investment

Most EC motors pay for themselves in 2 to 4 years thanks to:

- Major energy savings

- Less mechanical maintenance

- Longer motor lifespan

But the Real Advantage Is Stability

A motor programmed to run at 1,300 RPM will actually run at 1,300 RPM — even during wind gusts or pressure fluctuations inside the barn.

For producers, this means:

- More stable barn climate

- Better control of humidity and temperature

- Improved animal comfort and performance

And This Is Just the Beginning

EC motors are designed for today’s farms… and tomorrow’s:

- Integrated Modbus communication

- Real-time data

- Remote fine-tuning

- Simpler installation than AC systems

Yes, EC motors are profitable.

But what producers notice first is their stability and the potential of everything that follows.

Don't miss this opportunity to stay informed!

Explore our dedicated page for agricultural professionals and discover practical tips and valuable insights to enhance the quality of your livestock production, streamline your daily tasks, and increase profitability.

Search for a post ?

Our Categories

Recent posts

Newsletter

Stay up-to-date and don’t miss any important information.

Subscribe to our newsletter!